Summary of Motionnet

“The Motionnet” is based on the international standard: “SEMI standard”.Motionnet is a super high speed serial communication system based on the Serial Communication LSI: G9000 Series. Motionnet is a total Less Wiring system with the serial communication at high speed of 20Mbps. Not to mention input and output control and motor control, which are required by FA field, you can remote control CPU emulation and message communication by making use of rapidity.

Semi Standard Conformity

The Motionnet, which is a Serial Communication System, has acquired SEMI E54.21: Specification for Sensor Actuator Network for Motionnet Communication.” “SEMI standard” is used as the industrial standard of semi-conductors, FPD, PV manufacturing industry all over the world, and the “Motionnet”, which is based on this standard, can be used as the global standard of system network.Motionnet Network

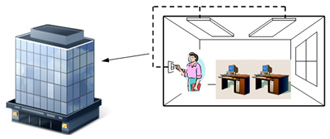

Automatic assembling machines and measuring machines consist of a variety of modules such as I/O and motor control. The Motionnet connects those modules with a communication line(single cable) and controls them from the host side. The system base is the Motionnet.

Features of Motionnet

| 1. Remote Control | You can control dispersed modules from the Center using a serial communication. You can connect 64 modules and the maximum cable length is 100m. |

|---|---|

| 2. Communication LSI | A variety of LSIs are provided for communication, and those LSIs are connected through RS-485. You can perform multi-purpose controls such as I/O control, motor control, and analog control. |

| 3. Motor control | The motor control communication LSI has the pulse control functions. You can get a complicated control such as motion/speed/and origin return simply by sending the data. Maximum 64 motors can be controlled, and linear and circular interpolation can be done by the communication. |

| 4. Multi-purpose control | The CPU emulation control LSI allows you control a variety of LSIs which are located in the remote places. This LSI has a function to realize the CPU bus artificially by serial communications, and can be connected with any kind of 8 or 16 bit LSI. For example, various controls such as analog controls and multi axis motor control, and a lot more controls can be considered. |

| 5. System construction is simple | The Serial communication part is all done by the hardware, so it is rare that software intervenes in the communications. Therefore, the burden of CPU to control is small. There is no need for high speed CPU and for a special program for communication. |

Specifications of Motionnet

Motionnet uses both Cyclic Communication to communicate sequentially and regularly with local devices and Transient Communication to send the data when required. Cyclic Communication transits I/O data and motor control status, while Transient Communication transits motor’s motion /speed data. The communication frame configuration is so simple and the interval between the frames is so small, that the communication is efficient.| Communication rate | 20Mbps |

|---|---|

| Communication time | Cyclic communication: 15.1μsec/ station 4 bytes Transient communication: 169.3μsec/station 256 bytes |

| # of controllable local device | 64 stations When all stations are for I/O control, 2048 points (max) When all stations are for motor control. 64 axes (max) Motor selection : Free Motor control : PtoP/Circle・Circular/ Linear interpolation |

| Topology | Bus type network |

| Communication control type | Cyclic communication, Transient communication |

| Data frame length | Cyclic communication 4 bytes/ station Transient communication 256 bytes/station (max) |

| Retry | Three times (In Transient communication) |

| Physical layer | RS485, Half duplex communication |

| Insulation type | Pulse transformer |

| Cable length | 100m(max) / 0.8m(min) |

| Communication LSI | G9001A, G9002A, G9103B, G9004A |

Communication by Motionnet

In communication type, there are the Cyclic communication, which is always communicating, and the Transient communication, which is done by the timing instructed by the CPU. Transient communications transit data interrupting between the Cyclic communications. In Cyclic communication, you always transit 4 byte port information(I/O data, motor control status) so that you are able to update the RAM in the center LSI automatically. Transient communication is mainly used for data commination, you will transit data by the commands from CPU using the 512 byte RAM(FIFO). Motionnet is designed to make the Request flames, Response flames and furthermore the interval between the frames, short as possible. That allows the shortest communication time.| Communication control type | Communication Type | |

|---|---|---|

| Cyclic communication (Always) | I/Ocommunication | Send and receive Local ports information |

| Transient communication (Interrupt) | Data communication | Send and receive data |

| System communication | Send and receive attribute information (device address) | |

| Broadcast communication | Send commands to multiple locals (G9103B) simultaneously. | |

| Break communication | Send to confirm the local device participation on the way. | |

- Flexible with additional I/O and motor as well as the alteration.

- Easily build original communication lines

- Any motor manufacturers can be used

- Motor control program is the same

- Motor speed pattern is changed easily

- Software license is not necessary

- Response speed is faster than the other manufacturers

- Not depend on the CPU performance

- Good communication speed and cost performance

- Little software and hardware burdens for system constructions

Illumination control

Illumination control

Centralized control type coin locker

Centralized control type coin locker

Semiconductor manufacturing machine

Mask/ Reticle manufacturing machine (Washing device)

Semiconductor manufacturing machine

Mask/ Reticle manufacturing machine (Washing device) Assembling machine (Dicing machine/Bonding machine)

Inspection machine (Handling machine)

Physical and chemistry apparatus

Physical and chemistry apparatus

Vending machine

Vending machine

Washing machine manufacturer

Semiconductor manufacturing machine

“We do not need so many axes in the machines we provide. The important point is to realize the higher level control than sequencers in order to evolve the washing process in accordance with the progress of the semiconductor technologies. In the sense, we find the Motionnet very advantageous.”

Machine manufacturer

Motor assembling line

“We are developing an automatic machine with 6 axes of servo motors, 1 axis of stepping motor, and 450 points of I/O while we are debugging the movements, so we do not know what will happen before we move the machine. It is good that we can flexibly add mechanisms in terms of the hardware and software.”

As for the support products, please refer to the website of each company.

Hivertec, Inc.

Techno-Holon Corporation

Kohzu Precision Co., Ltd.

Taiwan Pulse Motion

Nippon Pulse Motor Co., Ltd.

Hivertec, Inc.

Techno-Holon Corporation

Kohzu Precision Co., Ltd.

Taiwan Pulse Motion

Nippon Pulse Motor Co., Ltd.